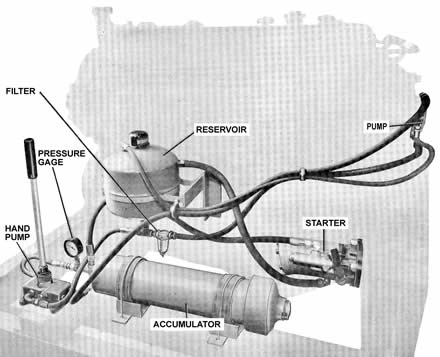

The accumulator would then be fully charged and in balance. So, now imagine that all three accumulators are fully charged. They are piped in parallel with hydraulic tubing. The tubing runs forward to to each engine, which was equipped with a hydraulic starting motor. They looked similar to an electric starter, somewhat smaller. And here is why: Inside the hydraulic starting motor were six or eight small hydraulic pistons, looking somewhat like a gatling gun, which received the full force of the 3,000 psi fluid against them when the start button was pushed by the coxswain while he was seated at the helm. The start button energized a solenoid-operated hydraulic valve, which sent the starting motor spinning and producing something like twenty horsepower! Much more powerful than an electric starting motor. So, those hydraulic starting motors would spin the engines faster and the engines would start sooner. Under ideal conditions, we could get aboard, start the engines, disconnect the 240 volt electrical cable, cast off the mooring lines and be underway in one minute or less.

The accumulator would then be fully charged and in balance. So, now imagine that all three accumulators are fully charged. They are piped in parallel with hydraulic tubing. The tubing runs forward to to each engine, which was equipped with a hydraulic starting motor. They looked similar to an electric starter, somewhat smaller. And here is why: Inside the hydraulic starting motor were six or eight small hydraulic pistons, looking somewhat like a gatling gun, which received the full force of the 3,000 psi fluid against them when the start button was pushed by the coxswain while he was seated at the helm. The start button energized a solenoid-operated hydraulic valve, which sent the starting motor spinning and producing something like twenty horsepower! Much more powerful than an electric starting motor. So, those hydraulic starting motors would spin the engines faster and the engines would start sooner. Under ideal conditions, we could get aboard, start the engines, disconnect the 240 volt electrical cable, cast off the mooring lines and be underway in one minute or less. The engines either started within a few seconds, or they didn't start at all. One of the reasons that they wouldn't start was because the engines had cooled off. The engines cooled off because the KIM Hotstarts had failed or there was an electrical failure in the system which supplied the Hotstarts. Or because someone forgot to plug the power cable from the dock into the boat when it was being moored. Yes, that happened a few times. We remedied that quickly, believe me. Even if the KIM Hotstarts were working properly, it was also vital that the engines' fuel systems be completely free of any entrapped air. Whenever we changed the fuel filters or did any kind of repairs to the fuel systems, great care had to be taken to completely purge all air bubbles. Diesel fuel systems only function correctly if there is nothing but fuel within. Any entrapped air will act like an accumulator and prevent the pump from spraying the fuel into each cylinder. The result? The engines will crank, but they won't fire. Once the starting attempt had failed, the boat was rendered useless to us. If the boat crew was getting underway on a rescue call, they would have to immediately switch to another boat, if one was available. In order to return the useless boat back into ready condition, much work was required. This involved finding and repairing the original problem, and then recharging the starting system's accumulators. The only way to do that was to pump the system up from 1500 psi to 3000 psi, using the manually operated hydraulic pump, located in the engine compartment. The pump was mounted thwart ships (crossways) on the bilge frame, even with the deck plate and between the reduction gears. A steel bar was stowed in the engine compartment, and this was placed into the linkage on the pump. It took two people, one on each side, to provide the necessary "steam" needed to push that pump bar back and forth. At the beginning, with the system pressure at 1500 psi, the effort required was not excessive. But, as the system pressure rose, it became increasingly difficult to operate the pump bar. Add to this the cramped quarter and heat, and a team of two could only last ten or fifteen minutes before being relieved by two other men. It usually took around forty-five minutes to fully recharge the system. Most of the time the engineers would do the pumping, but there were times when the deck force would pitch in and help, which was appreciated by us. It should be pointed out that the port engine had a hydraulic pump mounted on it to recharge the accumulators after a normal start. It was for this reason that the coxwain always started the port engine first. Once the engine started, it would recharge the accumulators automatically. The need to use the hand pump only arose when the port engine would not start.

The engines either started within a few seconds, or they didn't start at all. One of the reasons that they wouldn't start was because the engines had cooled off. The engines cooled off because the KIM Hotstarts had failed or there was an electrical failure in the system which supplied the Hotstarts. Or because someone forgot to plug the power cable from the dock into the boat when it was being moored. Yes, that happened a few times. We remedied that quickly, believe me. Even if the KIM Hotstarts were working properly, it was also vital that the engines' fuel systems be completely free of any entrapped air. Whenever we changed the fuel filters or did any kind of repairs to the fuel systems, great care had to be taken to completely purge all air bubbles. Diesel fuel systems only function correctly if there is nothing but fuel within. Any entrapped air will act like an accumulator and prevent the pump from spraying the fuel into each cylinder. The result? The engines will crank, but they won't fire. Once the starting attempt had failed, the boat was rendered useless to us. If the boat crew was getting underway on a rescue call, they would have to immediately switch to another boat, if one was available. In order to return the useless boat back into ready condition, much work was required. This involved finding and repairing the original problem, and then recharging the starting system's accumulators. The only way to do that was to pump the system up from 1500 psi to 3000 psi, using the manually operated hydraulic pump, located in the engine compartment. The pump was mounted thwart ships (crossways) on the bilge frame, even with the deck plate and between the reduction gears. A steel bar was stowed in the engine compartment, and this was placed into the linkage on the pump. It took two people, one on each side, to provide the necessary "steam" needed to push that pump bar back and forth. At the beginning, with the system pressure at 1500 psi, the effort required was not excessive. But, as the system pressure rose, it became increasingly difficult to operate the pump bar. Add to this the cramped quarter and heat, and a team of two could only last ten or fifteen minutes before being relieved by two other men. It usually took around forty-five minutes to fully recharge the system. Most of the time the engineers would do the pumping, but there were times when the deck force would pitch in and help, which was appreciated by us. It should be pointed out that the port engine had a hydraulic pump mounted on it to recharge the accumulators after a normal start. It was for this reason that the coxwain always started the port engine first. Once the engine started, it would recharge the accumulators automatically. The need to use the hand pump only arose when the port engine would not start.